Valve Timing Diagram for 4-Stroke Engine (petrol and diesel) As we all know in 4-stroke engine the cycle completes in 4-strokes that are suction, compression, expansion and exhaust, The relation between the valves (inlet and outlet) and piston movement from TDC to BDC is represented by the graph known as valve timing diagram. Diesel Engine, Diesel Generator, Power Generator manufacturer / supplier in China, offering Model No. Zs1115 4- Stroke Single Cylinder Diesel Engine, Sb 10-50 N 70-120 6NF-9/13.2.Rice Mill, High Mining Crushing Ratio and so on. Just after the piston moves to the bottom of its travel (bottom dead center), the cylinder bore contains the maximum air-fuel mixture possible. The intake valve closes and the piston returns back up the cylinder bore. This is called the compression stroke of the 4. The cylinder wall is a thin sleeve surrounding the piston head which creates a space for the combustion of fuel and the genesis of mechanical energy. A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. The Mechanic: Machine Shop Blog. Four Stroke Single Cylinder Engine. 0 Comments 0 Comments Leave a Reply. Motor Cycle Notes Course 1.

Four cylinder engines are the most fuel efficient internal combustion engines. They however have lower vibration and noise levels than the two stroke engines, but have a higher vibration level than a Wankel engine. They also have a lower power-to-weight ratio than a two stroke engine of comparable power output.

Enya engine

ENYA R.155.4C engine from modelflight.com

| engine | capacity in cc | power output in kWatts | J/ccfam |

|---|---|---|---|

| 120FS | 19.93 | 1.566 at 11,250 rpm | 0.838 |

| R.155.4C | 25.42 | 1.86 at 11,250 rpm | 0.780 |

Notes

- All Enya engines use ' glow fuel' : methanol + 5 to 15 % nitromethane + 16% minimum synthetic castor oil lubricant.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- For RCVxx-CD, J/ccfam = ( power_in_watts x 60 x 2 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

O.S. Engines

O.S. Engines FS-70 Ultimate high performance, four stroke, engine with a fuel pump. Photograph from www.osengines.com

O.S. Engines FT-300 two cylinder engine from www.osengines.com

| engine | cylinders | capacity in cc | weight in kg | power output in kWatts | kW / kg | J/ccfam |

|---|---|---|---|---|---|---|

| FS-70 Ultimate | 1 | 11.45 | 0.502 | 0.894 at 11,000 rpm | 1.781 | 0.852 |

| FS-91 S II | 1 | 15 | 0.649 | 1.193 at 11,000 rpm | 1.838 | 0.868 |

| FS-120S III | 1 | 20 | 0.921 | 1.56 at 12,000 rpm | 1.694 | 0.76 |

| FT-160 | 2 | 26.5 | 1.1 | 1.49 at 10,000 rpm | 1.354 | 0.675 |

| FS-200U | 1 | 32.4 | 0.83 | 2.16 at 9,000 rpm | 2.605 | 0.890 |

| FT-300 | 2 | 49 | 1.828 | 3.0 at 7,000 rpm | 1.641 | 1.050 |

| FF-300 radial | 5 | 49.7 | 2.673 | 3.0 at 8,000 rpm | 1.122 | 0.905 |

| FF-320 | 4 | 53.2 | 2.19 | 3.06 at 8,000 rpm | 1.37 | 0.846 |

Notes

- All O.S. engines use ' glow fuel' : methanol + 5 to 15 % nitromethane + 16% minimum synthetic castor oil lubricant.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- For RCVxx-CD, J/ccfam = ( power_in_watts x 60 x 2 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

The O.S. Engines FF-320 'flat four' from osengines.com/engines/osmg1320.html

SAITO single cylinder engines

The SAITO 180 engine. Photograph from horizonhobby.com

| Saito Engine | capacity in cc | weight in kg | power output in kWatts | Power-to-Weight in kWatts/kg | min rpm | max rpm | fuel efficiency in J/ccfam |

|---|---|---|---|---|---|---|---|

| FA-45S | 7.50 | 0.440 | 0.522 | 1.186 | 2,000 | 12,000 | 0.696 |

| FA-50 | 8.20 | 0.435 | 0.634 | 1.457 | 2,000 | 12,000 | 0.773 |

| FA-56 | 9.20 | 0.410 | 0.671 | 1.637 | 2,000 | 12,000 | 0.729 |

| FA-56F | 9.20 | 0.410 | 0.671 | 1.637 | 2,000 | 12,000 | 0.729 |

| FA-62a | 10.24 | 0.469 | 0.746 | 1.590 | 2,000 | 12,000 | 0.728 |

| FA-65 | 10.60 | 0.550 | 0.708 | 1.288 | 2,000 | 12,000 | 0.668 |

| FA-72 | 11.80 | 0.470 | 0.895 | 1.904 | 2,000 | 12,000 | 0.758 |

| FA-80 | 13.10 | 0.540 | 0.969 | 1.795 | 2,000 | 12,000 | 0.740 |

| FA-82a | 13.80 | 0.453 | 1.119 | 2.469 | 2,000 | 12,000 | 0.811 |

| FA-91S | 15.00 | 0.555 | 1.193 | 2.150 | 2,000 | 11,000 | 0.868 |

| FA-100 | 17.10 | 0.551 | 1.342 | 2.436 | 2,000 | 11,000 | 0.856 |

| FA-120S | 20.00 | 0.900 | 1.641 | 1.823 | 1,900 | 10,500 | 0.937 |

| FA-125a | 20.52 | 0.700 | 1.641 | 2.344 | 1,800 | 10,500 | 0.914 |

Notes

- All Saito engines use ' glow fuel' : methanol + 5 to 15 % nitromethane + 16% minimum synthetic castor oil lubricant.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- For RCVxx-CD, J/ccfam = ( power_in_watts x 60 x 2 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

SAITO multi-cylinder engines

Images from horizonhobby.com

The 'vibration-free' SAITO FA-182TD.

The Saito FA-300T twin engine.

The SAITO FA-170R three cylinder radial engine.

The Saito FA-325R5 radial engine.

Engine trends for four stroke engines

Pout scales with engine capacity as Pout = 0.073 * x + 0.031 for Pout in kWatts, where x is the engine capacity in cc.

The average power-to-weight ratio for the above engines is 1.727 kWatts / kg. The superiority of the Saito engines in respect of power-to-weight ratios is clear.

The average engine efficiency for the above engines is 0.813 J / ccfam. For the Saito engines, we notice the engine efficiency saturates for engines with a capacity of 17 cc and above.

The Briggs & Stratton 4-stroke engine, also referred to as a 4-cycle engine, powers an array of outdoor power equipment, including lawn mowers, generators, lawn tractors and tillers. Our 4-stroke engines lead the world in production and quality.

What Makes 4-Stroke Overhead Valve Engines Different?

In overhead valve (OHV) engines, the valves are positioned above the piston. The camshaft moves the valves through a tappet, pushrods and rocker arms. 4-stroke OHV engines provide more efficient combustion by allowing the air-fuel mixture to spread more evenly throughout the combustion chamber.

In order to power your equipment, the overhead valve engine completes a repeating 4-step process detailed below.

Element that Allow Internal Combustion Engines to Run

- Air

- Fuel

- Compression

- Spark

Step 1: Intake Stroke

Air and fuel enter the small engine through the carburetor. It’s the job of the carburetor to supply a mixture of air and fuel that will allow for proper combustion. During the intake stroke, the intake valve between the carburetor and combustion chamber opens. This allows atmospheric pressure to force the air-fuel mixture into the cylinder bore as the piston moves downward.

>> Having performance problems? Find out how to troubleshoot carburetor repair and clean / maintain your small engine carburetors.

Step 2: Compression Stroke

Four Cylinder Engines

Just after the piston moves to the bottom of its travel (bottom dead center), the cylinder bore contains the maximum air-fuel mixture possible. The intake valve closes and the piston returns back up the cylinder bore. This is called the compression stroke of the 4-stroke engine process. The air-fuel mixture is compressed between the piston and cylinder head.

Four Stroke Single Cylinder Engine

Step 3: Power Stroke

When the piston reaches the top of its travel (top dead center), it will be at its optimum point to ignite the fuel to get maximize power to your outdoor power equipment. A very high voltage is created in the ignition coil. The spark plug enables this high voltage to be discharged into the combustion chamber. The heat created by the spark ignites the gases, creating rapidly expanding, super-heated gases that force the piston back down the cylinder bore. This is called the power stroke.

Step 4: Exhaust Stroke

When the piston reaches bottom dead center again, the exhaust valve opens. As the piston travels back up the cylinder bore, it forces the spent combustion gases through the exhaust valve and out of the exhaust systems. As the piston returns to top dead center, the exhaust valve closes and the intake valve opens and the 4-stroke engine process repeat.

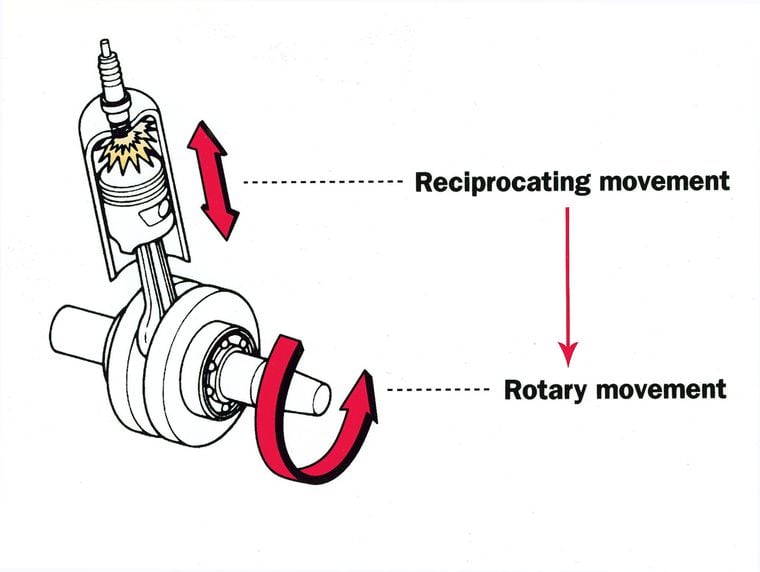

Ever repetition of the cycle requires two full rotations of the crankshaft, while the engine only creates power during one of the four strokes. To keep the machine running, it needs the small engine flywheel. The power stroke creates momentum that pushes the flywheel’s inertia keeps it and the crankshaft turning during the exhaust, intake and compression strokes.

Learn how to safely use, troubleshoot and maintain your Briggs & Stratton equipment.

View solutions for your maintenance and repair questions.